Process

Casting

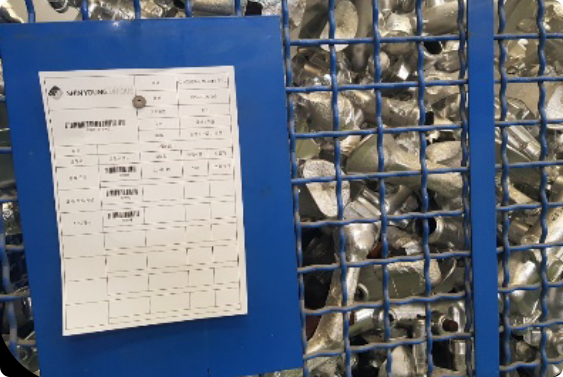

01. Raw MaterialInspect the raw material (FIFO) for warehousing

01. Raw MaterialInspect the raw material (FIFO) for warehousing  02. Gas Bubbling FiltrationRemove the hydrogen gas generated in the molten metal

02. Gas Bubbling FiltrationRemove the hydrogen gas generated in the molten metal 03. Inspection of moldCheck the hydrogen gas rate inside the specimen of the molten metal by measuring the density of the specimen

03. Inspection of moldCheck the hydrogen gas rate inside the specimen of the molten metal by measuring the density of the specimen 04. Tool SettingMount the mold on the equipment and spray a coating material to improve the releasing property and roughness of the mold and the product

04. Tool SettingMount the mold on the equipment and spray a coating material to improve the releasing property and roughness of the mold and the product 05. CastingInject the molten aluminum to the mold after completing the molten metal test

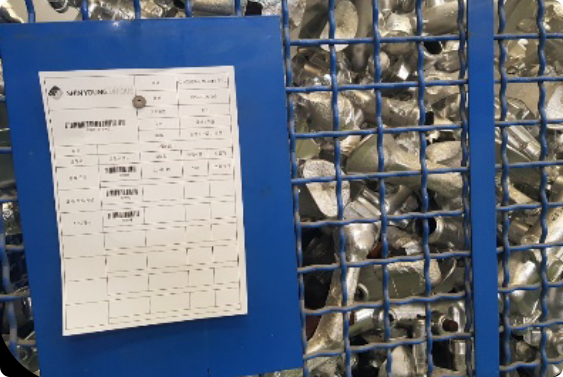

05. CastingInject the molten aluminum to the mold after completing the molten metal test 06. LOT DistinguishIndicate as semi-finished products after the casting process is completed

06. LOT DistinguishIndicate as semi-finished products after the casting process is completed

POST - Casting

07. DecoringRemove the R.C.S. used for the inner flow path

07. DecoringRemove the R.C.S. used for the inner flow path 08. CuttingRemove the product’s riser, inlet, etc.

08. CuttingRemove the product’s riser, inlet, etc.  09. DeburringPerform inspection according to components standards

09. DeburringPerform inspection according to components standards 10. Heat treatmentImprove the product’s physical properties by applying heat.

10. Heat treatmentImprove the product’s physical properties by applying heat. 11. Shot blastBeat the product surface with a small SUS ball to make it smooth or remove stress

11. Shot blastBeat the product surface with a small SUS ball to make it smooth or remove stress 12. InspectionInspect the product’s appearance and major parts before shipping

12. InspectionInspect the product’s appearance and major parts before shipping

Machining

13. MachiningUse the tools to meet the dimensional requirements of a customer

13. MachiningUse the tools to meet the dimensional requirements of a customer 14. WashingRemove the residual cutting oil from the product

14. WashingRemove the residual cutting oil from the product  15. Leak TestTest the air-tightness of the product

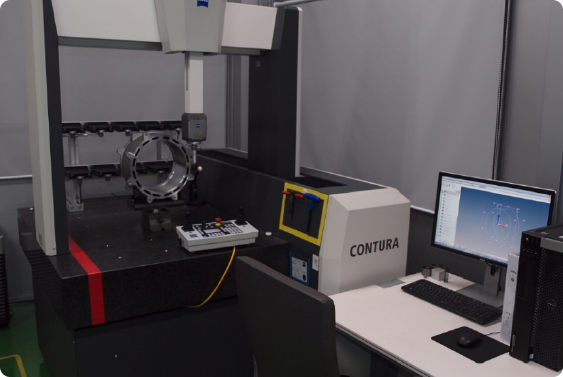

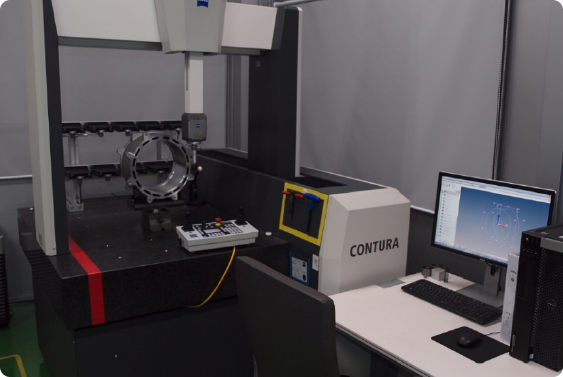

15. Leak TestTest the air-tightness of the product 16. InspectionInspect dimensions and appearance of the product

16. InspectionInspect dimensions and appearance of the product 17. PackingPack the product according to the specifications discussed with the customer

17. PackingPack the product according to the specifications discussed with the customer 18. ShipmentDeliver the product to the customer

18. ShipmentDeliver the product to the customer

01. Raw MaterialInspect the raw material (FIFO) for warehousing

01. Raw MaterialInspect the raw material (FIFO) for warehousing  02. Gas Bubbling FiltrationRemove the hydrogen gas generated in the molten metal

02. Gas Bubbling FiltrationRemove the hydrogen gas generated in the molten metal 03. Inspection of moldCheck the hydrogen gas rate inside the specimen of the molten metal by measuring the density of the specimen

03. Inspection of moldCheck the hydrogen gas rate inside the specimen of the molten metal by measuring the density of the specimen 04. Tool SettingMount the mold on the equipment and spray a coating material to improve the releasing property and roughness of the mold and the product

04. Tool SettingMount the mold on the equipment and spray a coating material to improve the releasing property and roughness of the mold and the product 05. CastingInject the molten aluminum to the mold after completing the molten metal test

05. CastingInject the molten aluminum to the mold after completing the molten metal test 06. LOT DistinguishIndicate as semi-finished products after the casting process is completed

06. LOT DistinguishIndicate as semi-finished products after the casting process is completed 07. DecoringRemove the R.C.S. used for the inner flow path

07. DecoringRemove the R.C.S. used for the inner flow path 08. CuttingRemove the product’s riser, inlet, etc.

08. CuttingRemove the product’s riser, inlet, etc.  09. DeburringPerform inspection according to components standards

09. DeburringPerform inspection according to components standards 10. Heat treatmentImprove the product’s physical properties by applying heat.

10. Heat treatmentImprove the product’s physical properties by applying heat. 11. Shot blastBeat the product surface with a small SUS ball to make it smooth or remove stress

11. Shot blastBeat the product surface with a small SUS ball to make it smooth or remove stress 12. InspectionInspect the product’s appearance and major parts before shipping

12. InspectionInspect the product’s appearance and major parts before shipping 13. MachiningUse the tools to meet the dimensional requirements of a customer

13. MachiningUse the tools to meet the dimensional requirements of a customer 14. WashingRemove the residual cutting oil from the product

14. WashingRemove the residual cutting oil from the product  15. Leak TestTest the air-tightness of the product

15. Leak TestTest the air-tightness of the product 16. InspectionInspect dimensions and appearance of the product

16. InspectionInspect dimensions and appearance of the product 17. PackingPack the product according to the specifications discussed with the customer

17. PackingPack the product according to the specifications discussed with the customer 18. ShipmentDeliver the product to the customer

18. ShipmentDeliver the product to the customer